Home > Nautical solutions > Components

Components

DOORTEX MARINE provides components related to traction units, motion transmission, command systems, and electronic cards that are selected for specific projects.

Traction unit

Depending on the leaves’ weight, required speed, and other specifics from shipyard and certifying agency, traction units are composed of an AC, or DC, or BLDC electric motor, coupled to a gearbox

Download

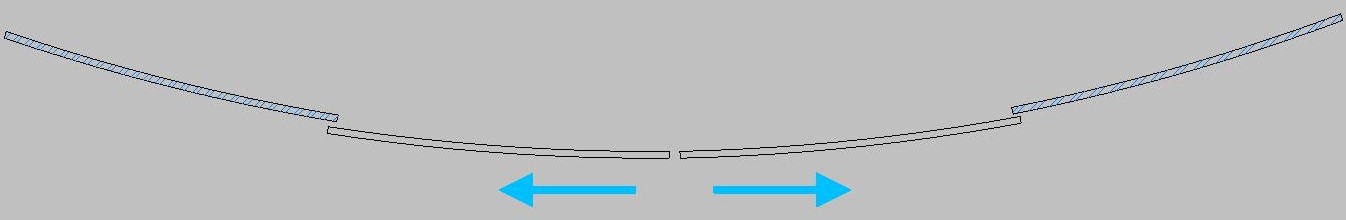

Motion transmission

The movement is transmitted from the traction unit to the leaves through a polyurethane belt with an HTD profile. On the inside of the structure, there are several steel strands, while the outside structure is shielded in nylon. This sandwich-based assembly ensures high traction resistance and high protection against humidity and corrosion, that are typical nautical conditions. The traction pulleys are made of anti-corrosion steel and are keyed on the gear with conical inserts

Download

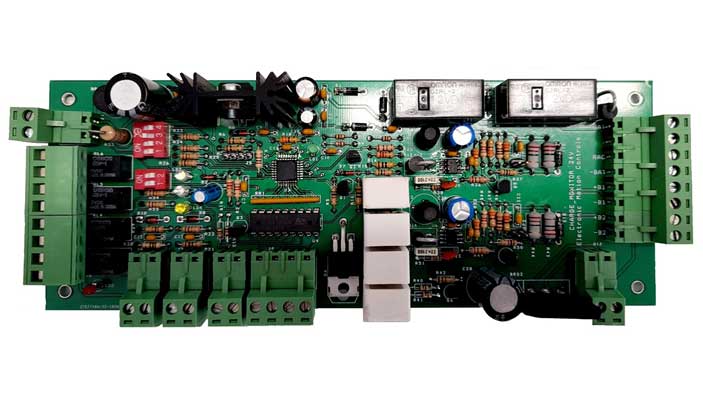

Electronic Command Board

The automatic door functioning is operated by our M.A.T system, representing years of experience and continuous development. In this operating system, designed for both DC and AC motors, all peripherals continuously interact with each other, allowing constant control of the automatic motion, safety, and monitoring functions.

The M.A.T. system is composed of the following peripherals:

dMotion

This electronic card is based on a 32-bit ARM controller and was developed exclusively for the nautical sector. It operates on the traction-unit and supervises all peripheral functions.

Emergency opening

In the event of a power failure, this electronic board allows the doors to be opened. This is possible thanks to the interconnection of the electronic board with dMotion, the switching program and two sealed batteries. Once the doors have been opened, the system is disabled and restarts automatically when the power is restored

Anti-black-out system

This system, connected with the dMotion card and the switch program, allows the regular functioning of the automatic door even in case of energy blackout. This peripheral is operated by a microprocessor and composed of 3 distinct units: the first unit recharges each battery, and once the energy charge threshold is reached, the energy level is lowered to an optimal value for its maintenance over time. The second unit monitors the battery by testing the charging level as well as the accumulator’s efficiency every 300 seconds. The third unit protects the entire system by interrupting the functioning of the door before a critical level of discharge is reached, preventing irreparable damage to the door. In this specific phase, a function called “last run” is provided, which enables to open or close the door before the functioning of the door permanently stops.

User interface

Up to eight run templates can be selected with this device. The selection is made by means of a button and the chosen run model is indicated by LEDs and pictographs. The peripheral can be customized as desired, being able to choose the number and the models of run that can be set.

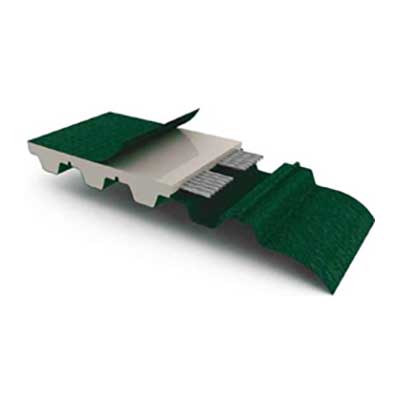

Inflatable gasket

The functioning of the inflatable gasket is controlled by an electronic card connected to the dMotion, the switch program, and the locking system. The integration of all units allows a safe, precise, and reliable functioning of the automatic door over time.

Pneumatic parts

“Compact” version system

Download

Command and Control Systems

For the control of the automation and its peripherals, a wide range of sensors and buttons connected to the dMotion board is available: from low-profile stainless-steel pushbuttons, with possible light indication, to sensors with active infrared and microwave technology, surface-mounted or flush-mounted. For selected and / or reserved accesses, an application for the Android system is available dApp, able, with your smartphone, to manage up to four different inputs.

Download

Security Systems

These peripherals units maintain the correct functioning and safe usage of automation. All security system units are connected to the dMotion card and are specific to the layout and positioning of the automatic door.

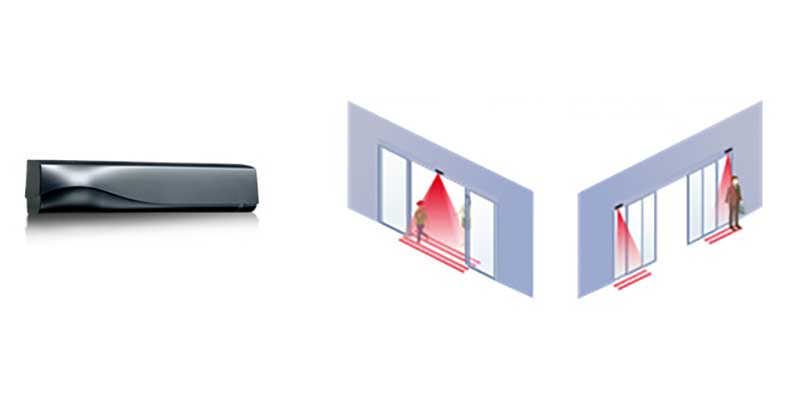

Infrared sensors

Based on active infrared and microwave technology, they are positioned high up, inside the false ceiling, allowing the monitoring of both the transit area and the lateral sliding area of the doors. They can be single or double coupled to the door start sensor

Photocell

Based on infrared transmitter/receiver system technology, the photocells have very compact dimensions and are installed on the fixed segments of the door. They are usually installed when infrared sensors cannot monitor the entire surface.

Sensitive edges

These sensors are typically used with curved doors, where the chance of having non-monitored areas is very high. Sensitive edges are constituted by two contact-based elements that are inserted in a thermoplastic elastomer and connected to an electronic control unit. Sensitive edges are installed with steel supports and are fixed on the anterior or posterior side of the sliding leaves. The high levels of commuting cycles make this component a reliable and long-lasting unit.

Optical barrier

Owing to a multi-radius curtain with a vertical scanner, optical barriers ensure the scanning of 180 cm for the entire transit zone. The very compact dimension of just 9 mm width allows the optical barrier to be hidden easily, and it is recommended when a single photocell sensor is not enough.

Download

Locking systems

To ensure a correct locking system of the doors (e.g. during sailing) there are two systems operated by the dMotion card and controlled by the switch program. The two systems are installed depending on the typology, dimensions, and usage of the automatic door.

Electromagnetic pin

It consists of an electrically controlled steel slider, which engages the doors on a dedicated shape, preventing them from sliding; the position is electronically monitored to prevent harmful malfunctions.

Retaining electromagnet

It is made up of a high-tightness solenoid, which acts magnetically on a plate mounted on the leaves, preventing any movement of the leaves.

Download

Remote Monitoring

All components of the M.A.T system are designed and created to monitor in real-time the door functioning from the dashboard, to have a constant report of all connected doors.

Opening Leaves configuration

The standard motors supplied by DOORTEX MARINE are designed for the movement of leaves having a maximum total weight up to 3,000 kg. The different configurable models are listed below. Different weight and configuration typologies will be discussed upon specific customer requests.

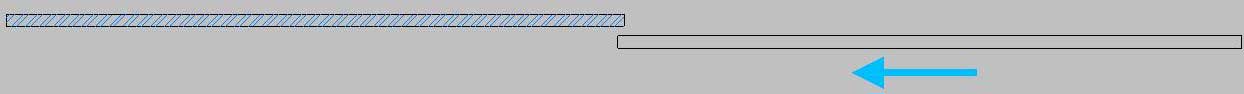

1AS

One lateral sliding door with right or left opening

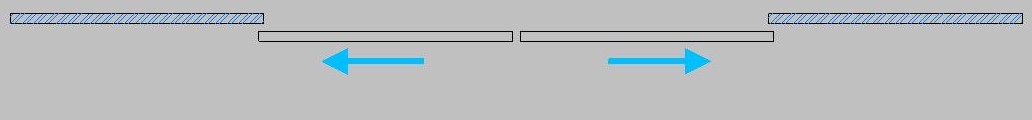

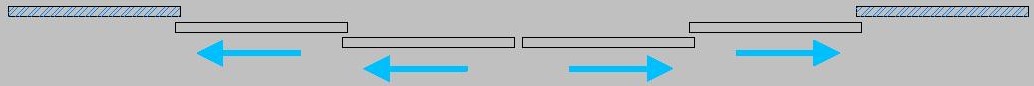

2AS

Two opposite sliding doors with central opening

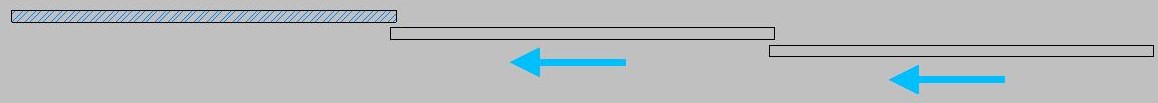

2AT

Two lateral sliding doors with simultaneous telescopic opening, left or right

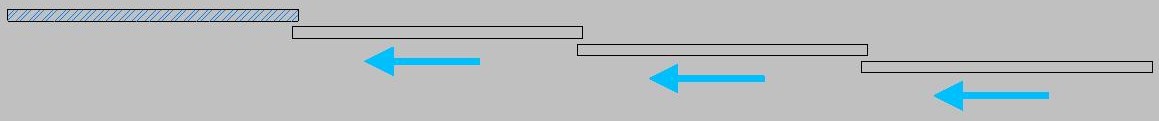

3AT

Three lateral sliding doors with simultaneous telescopic opening, left or right

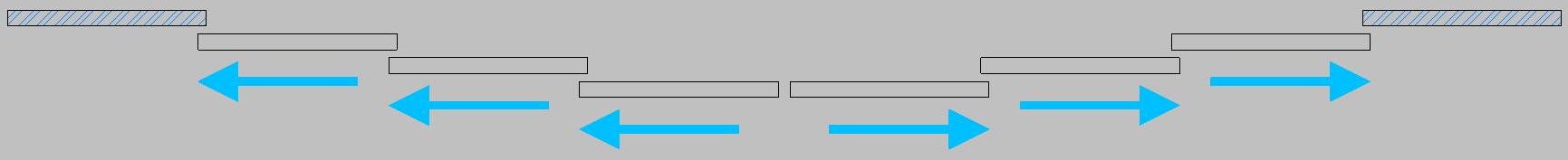

4ATC

Four opposite sliding doors with simultaneous and central telescopic opening

6ATC

Six opposite sliding doors with simultaneous and central telescopic opening

Curve

Two curve sliding doors opposite and with central opening